The Power of Epoxy: Crafting Durable Paddleboards for Unforgettable Adventures

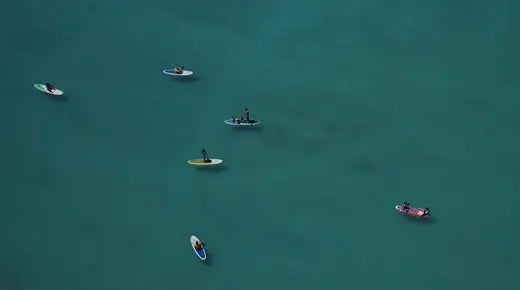

Paddleboarding has emerged as a beloved water sport, combining fitness, adventure, and tranquility on lakes and oceans alike. One of the secrets to the unmatched performance and durability of modern paddleboards lies in the type of materials used in their construction. Among these, epoxy resin stands out as a game-changer. In this article, we explore the pivotal role epoxy plays in creating paddleboards that not only endure the rigors of outdoor use but also offer an unparalleled paddling experience. Together, let’s glide into the exciting world of paddleboards, particularly the exemplary Voyager paddleboard.

Understanding Epoxy Resin

Epoxy resin is a synthetic polymer that has gained popularity across various industries due to its robustness and versatility. When cured, this resin transforms into a hard, durable, and chemically resistant material, making it ideal for crafting paddleboards. The combination of resin and hardener creates a strong bond that is crucial for the structural integrity of a paddleboard.

The Composition of Epoxy

Epoxy resin typically consists of two main components: the resin itself and the hardener. When combined, they undergo a chemical reaction which leads to the formation of a thermoset polymer. This process results in a rigid material that ensures:

- Strength: Provides exceptional tensile strength, making it less likely to crack or break under pressure.

- Flexibility: While strong, it maintains a slight flexibility, crucial for absorbing shocks during paddling.

- Water Resistance: Creates a waterproof barrier, essential for paddleboards constantly in contact with water.

- Lightweight: Allows the construction of lightweight boards without sacrificing strength, enhancing maneuverability.

Why Choose an Epoxy Paddleboard?

When selecting a paddleboard, the materials used can significantly impact performance and longevity. Let’s dive into the key reasons why epoxy paddleboards, such as the impressive Voyager paddleboard, have become the go-to choice for paddling enthusiasts.

Superior Durability

One of the most compelling benefits of epoxy is its resistance to wear and tear. Paddleboarding involves constant exposure to water, sunlight, and impact from various obstacles. Epoxy's durable nature ensures that boards maintain their aesthetic and structural integrity, even after extensive use. This longevity means that paddlers can fully immerse themselves in their adventures, knowing their equipment is built to last.

Enhanced Performance

Paddleboards constructed with epoxy tend to perform better than those made from other materials. The lightweight quality of epoxy allows for superior agility and speed on the water. The reduced weight also makes it easier for paddlers to transport and maneuver the board, enhancing the overall paddling experience, especially for those who frequently travel to different bodies of water.

Eco-Friendly Options

In recent years, many manufacturers have started using eco-friendly epoxy resins, prioritizing sustainability without sacrificing quality. This shift means that paddleboard enthusiasts can enjoy their favorite activities while being conscious of their environmental impact. As consumers increasingly seek to minimize their carbon footprint, eco-friendly paddleboards are becoming more popular.

How Epoxy Affects Paddleboard Design

The incorporation of epoxy resin allows for innovative designs in paddleboards, which enhance their overall functionality and appeal. Here are some ways that epoxy influences paddleboard design:

Custom Shapes and Sizes

Epoxy's flexibility in the molding process enables manufacturers to create paddleboards in various shapes and sizes tailored to different paddling styles and conditions. Whether it’s a wider board for beginners or a sleek, narrow design for racing enthusiasts, epoxy makes it possible.

Attractive Finishes

Epoxy resin provides a smooth, glossy finish that enhances the visual appeal of paddleboards. Custom graphics and colors can be incorporated seamlessly, making each board not only functional but also a canvas for artistic expression. The irresistible designs attract paddlers looking for both quality and style, further enhancing the allure of epoxy paddleboards like the Voyager paddleboard.

Increased Buoyancy

Epoxy’s lightweight properties contribute to the buoyancy of paddleboards. This ensures that paddlers remain stable, making it easier for them to maintain balance, even in choppy waters. Greater buoyancy translates into a more enjoyable experience out on the water, allowing for longer paddling sessions without fatigue.

Maintenance and Care for Epoxy Paddleboards

While epoxy paddleboards are designed for durability, taking proper care of them can extend their lifespan. Here are some maintenance tips for getting the most out of your Voyager paddleboard or any other epoxy model:

Regular Cleaning

After each use, rinse your paddleboard with fresh water to remove any salt, sand, or debris that could cause wear over time. A gentle cleaning solution can be used for stubborn spots, helping preserve the board’s finish.

Inspection for Damage

At regular intervals, check for any signs of damage such as scratches or chips. Early detection allows for timely repairs, preventing minor issues from escalating into major problems. Small scratches can often be repaired with epoxy filler, ensuring your paddleboard remains in optimal condition.

Proper Storage

Store your paddleboard in a cool, dry place, away from direct sunlight when not in use. Sun exposure can degrade the epoxy over time, leading to discoloration and weakening of the material. Using a board bag during transportation also protects against accidental dings and scratches.

The Future of Epoxy in Paddleboard Manufacturing

The landscape of paddleboarding is continually evolving, and the materials used in paddleboard construction mirror this change. As technology advances, we can expect even more innovative uses of epoxy resin in the design and manufacturing of paddleboards. Here are some trends we may see in the coming years:

Increased Customization

With advancements in digital design and manufacturing technology such as 3D printing, future paddleboards may see increased customization options. Paddlers will be able to create bespoke boards tailored to their preferences, abilities, and style, all underpinned by durable epoxy material.

Smart Paddleboards

Another exciting prospect is the integration of smart technology in paddleboards. Imagine paddleboards with built-in GPS, tracking systems, or sensors to monitor performance, all combined with the robust capability of epoxy materials. This merges traditional paddleboarding with modern technology, catering to a tech-savvy audience.

Eco-Conscious Innovations

As environmental awareness continues to rise, sustainable materials will likely become a focal point in the paddleboard industry. Innovations might include the development of bio-based epoxy resins or recycled materials to ensure that paddleboarding remains an eco-friendly sport.

Your Next Adventure Awaits

Choosing a paddleboard is about finding the right balance between performance, durability, and personal touch. Epoxy resin's contribution to creating strong, lightweight, and beautifully finished boards cannot be overstated. If you seek reliability on the water, look no further than epoxy paddleboards like the Voyager paddleboard, which exemplify the perfect marriage of technology and design.

Get ready to hit the water with confidence, knowing your paddleboard is equipped to handle the journey ahead. Adventure awaits, so equip yourself with an epoxy paddleboard that speaks to your passion for exploration. The waves are calling—are you ready to answer?